AAK Brazil

Achieves zero waste

AAK had a global objective for 2018 to achieve less

than 1.5 percent of its waste being sent to landfill.

Making a vital contribution to this goal, AAK Brazil

became a zero waste company in September 2018

through an innovative new initiative known as

”Coprocessing”.

Since 2016, AAK Brazil has endeavored to reduce

the amount of waste it sends to the municipal landfill.

However, over the last year, the site went much further

– instead of simply reducing the waste, it found a way to

dispose of it completely. As a result, AAK Brazil officially

became a zero waste company in September 2018,

setting a standard for all AAK sites to follow.

Making waste useful

Until recently, even following various initiatives to reduce

waste, AAK Brazil still shipped on average 3 MT a

month of waste to landfill. It was discovered that this

could be completely reversed thanks to a new process

known as Coprocessing.

Coprocessing is a technology that “blends” compatible

waste into a product that can be incinerated to fuel

cement kilns. This replaces fossil fuels and other raw

materials typically needed for the cement manufacturing

process and reduces the amount of harmful emissions

it creates. Not only does this have clearly beneficial

advantages for our environment, but it provides significant

cost savings for cement producers.

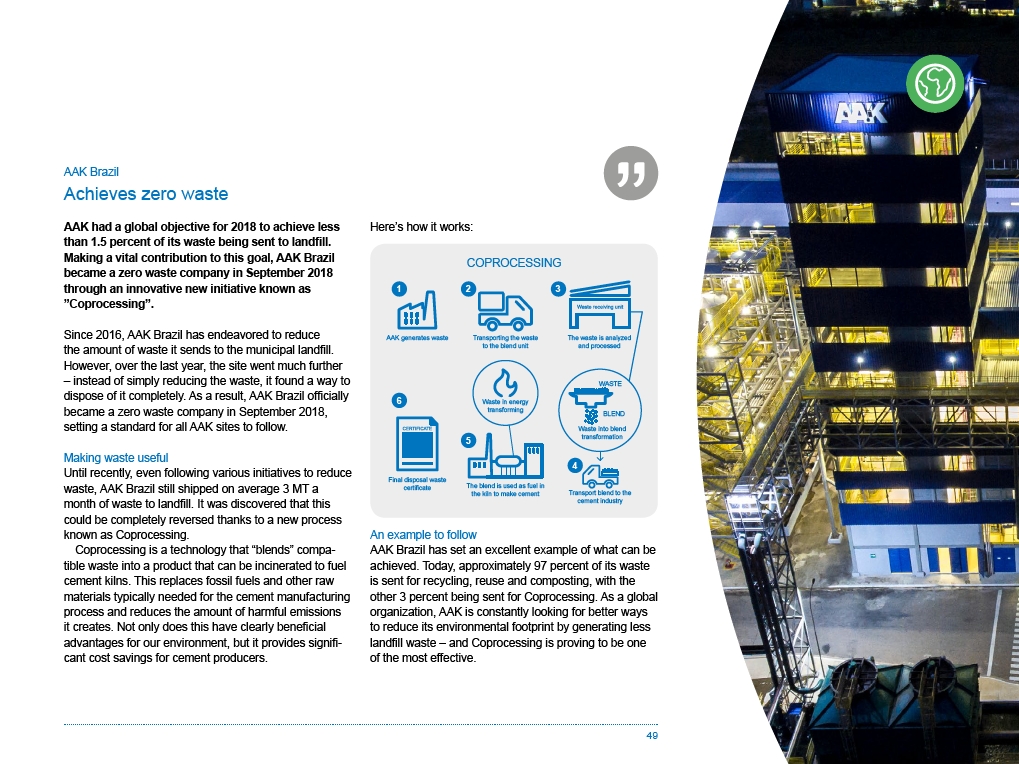

Here’s how it works:

COPROCESSING

1

AAK generates waste Transporting the waste

6

2

5

3

The waste is analyzed

4

to the blend unit

and processed

Final disposal waste

certificate

WASTE

BLEND

Waste into blend

transformation

Transport blend to the

cement industry

Waste in energy

transforming

The blend is used as fuel in

the kiln to make cement

An example to follow

AAK Brazil has set an excellent example of what can be

achieved. Today, approximately 97 percent of its waste

is sent for recycling, reuse and composting, with the

other 3 percent being sent for Coprocessing. As a global

organization, AAK is constantly looking for better ways

to reduce its environmental footprint by generating less

landfill waste – and Coprocessing is proving to be one

of the most effective.

49