AAK Colombia

Improving quality and reducing emissions

AAK Colombia has been finding better ways to measure

50

and improve the performance of its refinery. In

doing so, it has also been able to enhance product

quality and – crucially – reduce GHG emissions.

At AAK Colombia, we understand “refinement”. While on

one hand this relates directly to the industrial process

we manage, it also refers to our ongoing commitment

for improvement on the other. In particular, over the

last year we started to examine the performance of our

boiler. In doing so we began to find small issues that,

although only minor, we knew could be addressed to

give a higher quality production outcome.

Finding the trend

Working closely with our Maintenance department, we

discovered an unusual trend with the gas supply to our

boiler.

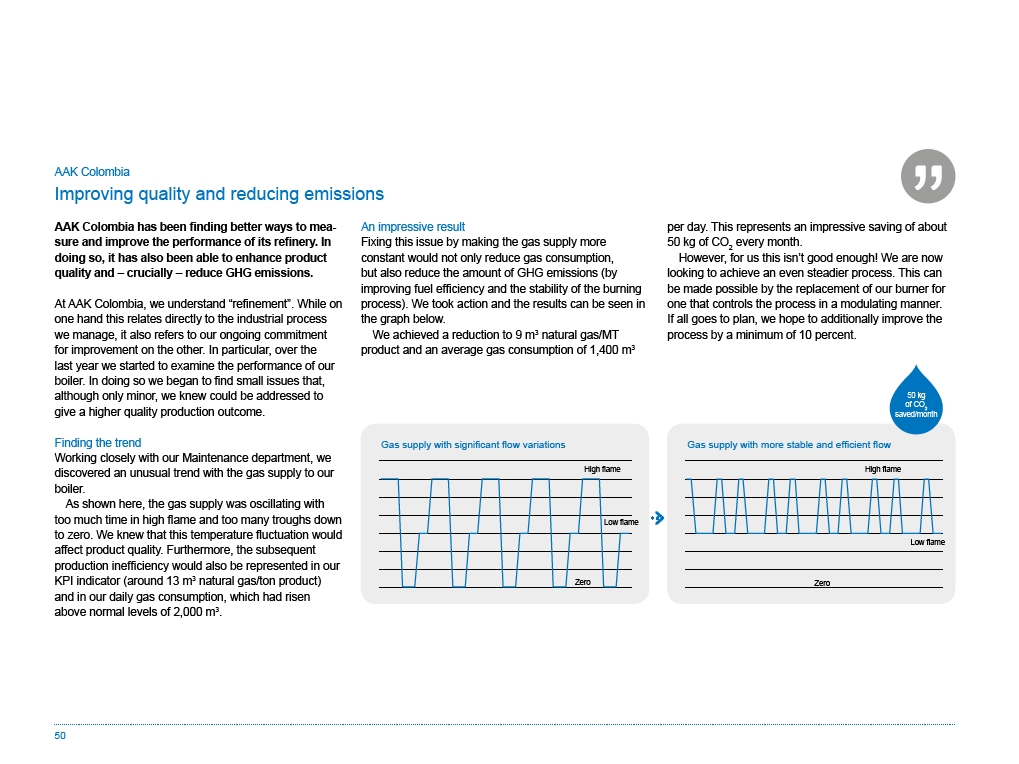

As shown here, the gas supply was oscillating with

too much time in high flame and too many troughs down

to zero. We knew that this temperature fluctuation would

affect product quality. Furthermore, the subsequent

production inefficiency would also be represented in our

KPI indicator (around 13 m3 natural gas/ton product)

and in our daily gas consumption, which had risen

above normal levels of 2,000 m3.

An impressive result

Fixing this issue by making the gas supply more

constant would not only reduce gas consumption,

but also reduce the amount of GHG emissions (by

improving fuel efficiency and the stability of the burning

process). We took action and the results can be seen in

the graph below.

We achieved a reduction to 9 m3 natural gas/MT

product and an average gas consumption of 1,400 m3

per day. This represents an impressive saving of about

50 kg of CO2 every month.

However, for us this isn’t good enough! We are now

looking to achieve an even steadier process. This can

be made possible by the replacement of our burner for

one that controls the process in a modulating manner.

If all goes to plan, we hope to additionally improve the

process by a minimum of 10 percent.

Gas supply with significant flow variations

High flame

Low flame

Zero

Gas supply with more stable and efficient flow

High flame

Low flame

Zero

50 kg

of CO2

saved/month