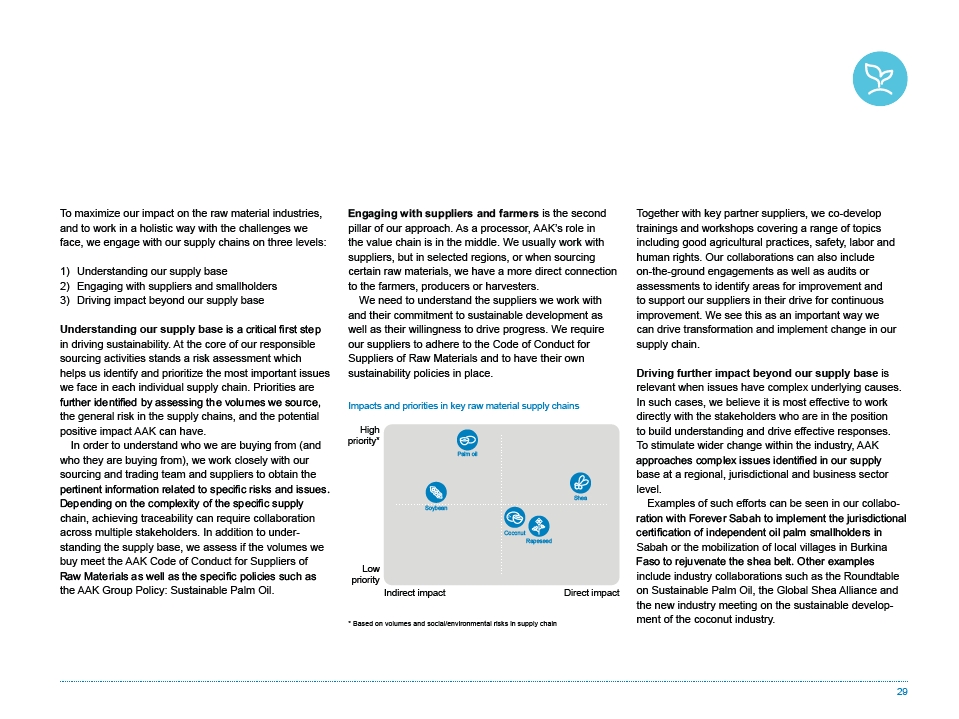

Impacts and priorities in key raw material supply chains

Palm oil

Soybean

Shea

Rapeseed

Coconut

29

(QJDJLQJZLWKVXSSOLHUVDQGIDUPHUVis the second

pillar of our approach. As a processor, AAK’s role in

the value chain is in the middle. We usually work with

suppliers, but in selected regions, or when sourcing

certain raw materials, we have a more direct connection

to the farmers, producers or harvesters.

We need to understand the suppliers we work with

and their commitment to sustainable development as

well as their willingness to drive progress. We require

our suppliers to adhere to the Code of Conduct for

Suppliers of Raw Materials and to have their own

sustainability policies in place.

Together with key partner suppliers, we co-develop

trainings and workshops covering a range of topics

including good agricultural practices, safety, labor and

human rights. Our collaborations can also include

on-the-ground engagements as well as audits or

assessments to identify areas for improvement and

to support our suppliers in their drive for continuous

improvement. We see this as an important way we

can drive transformation and implement change in our

supply chain.

Driving further impact beyond our supply base is

relevant when issues have complex underlying causes.

In such cases, we believe it is most effective to work

directly with the stakeholders who are in the position

to build understanding and drive effective responses.

To stimulate wider change within the industry, AAK

DSSURDFKHVFRPSOHLVVXHVLGHQWL¿HGLQRXUVXSSO\

base at a regional, jurisdictional and business sector

level.

Examples of such efforts can be seen in our collabo-

UDWLRQZLWK)RUHYHU6DEDKWRLPSOHPHQWWKHMXULVGLFWLRQDO

FHUWL¿FDWLRQRILQGHSHQGHQWRLOSDOPVPDOOKROGHUVLQ

Sabah or the mobilization of local villages in Burkina

)DVRWRUHMXYHQDWHWKHVKHDEHOW2WKHUHDPSOHV

include industry collaborations such as the Roundtable

on Sustainable Palm Oil, the Global Shea Alliance and

the new industry meeting on the sustainable development

of the coconut industry.

To maximize our impact on the raw material industries,

and to work in a holistic way with the challenges we

face, we engage with our supply chains on three levels:

1) Understanding our supply base

2) Engaging with suppliers and smallholders

3) Driving impact beyond our supply base

Understanding our supply base LVDFULWLFDO¿UVWVWHS

in driving sustainability. At the core of our responsible

sourcing activities stands a risk assessment which

helps us identify and prioritize the most important issues

we face in each individual supply chain. Priorities are

IXUWKHULGHQWL¿HGE\DVVHVVLQJWKHYROXPHVZHVRXUFH

the general risk in the supply chains, and the potential

positive impact AAK can have.

In order to understand who we are buying from (and

who they are buying from), we work closely with our

sourcing and trading team and suppliers to obtain the

SHUWLQHQWLQIRUPDWLRQUHODWHGWRVSHFL¿FULVNVDQGLVVXHV

'HSHQGLQJRQWKHFRPSOHLW\RIWKHVSHFL¿FVXSSO\

chain, achieving traceability can require collaboration

across multiple stakeholders. In addition to understanding

the supply base, we assess if the volumes we

buy meet the AAK Code of Conduct for Suppliers of

5DZ0DWHULDOVDVZHOODVWKHVSHFL¿FSROLFLHVVXFKDV

the AAK Group Policy: Sustainable Palm Oil.

High

priority*

Low

priority

Indirect impact

* Based on volumes and social/environmental risks in supply chain

Direct impact