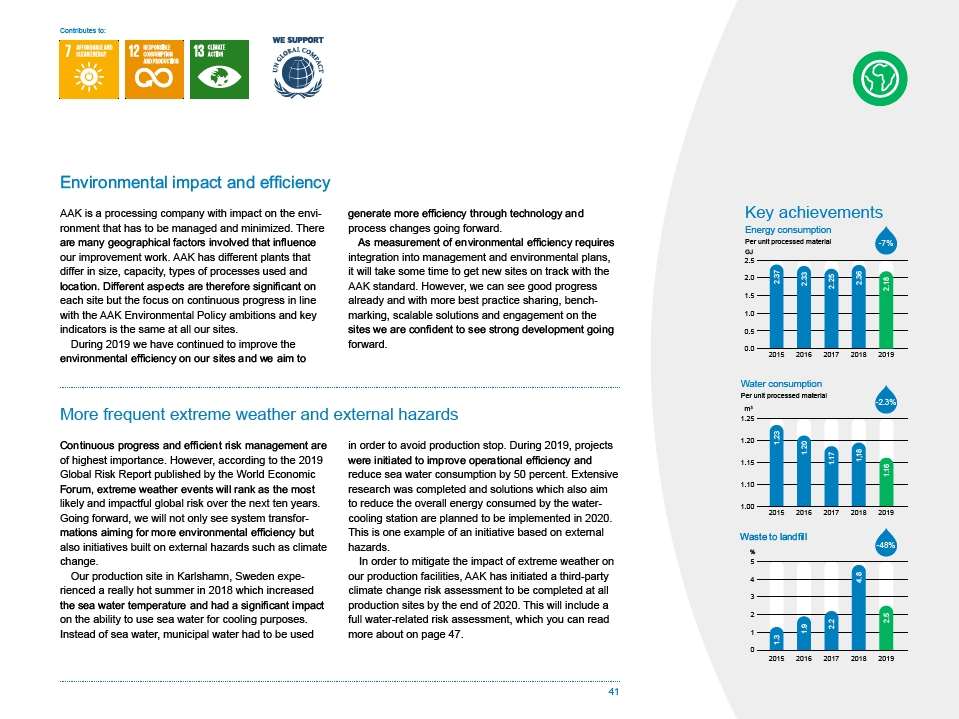

Key achievements

Energy consumption

Per unit processed material

-7%

2015 2016 2017 2018 2019

GJ

2.5

2.0

1.5

1.0

0.5

0.0

2.37

2.33

2.25

2.36

2.18

(QYLURQPHQWDOLPSDFWDQGHI¿FLHQF\

AAK is a processing company with impact on the environment

that has to be managed and minimized. There

DUHPDQ\JHRJUDSKLFDOIDFWRUVLQYROYHGWKDWLQÀXHQFH

our improvement work. AAK has different plants that

differ in size, capacity, types of processes used and

ORFDWLRQ'LIIHUHQWDVSHFWVDUHWKHUHIRUHVLJQL¿FDQWRQ

each site but the focus on continuous progress in line

with the AAK Environmental Policy ambitions and key

indicators is the same at all our sites.

During 2019 we have continued to improve the

HQYLURQPHQWDOHI¿FLHQF\RQRXUVLWHVDQGZHDLPWR

More frequent extreme weather and external hazards

&RQWLQXRXVSURJUHVVDQGHI¿FLHQWULVNPDQDJHPHQWDUH

of highest importance. However, according to the 2019

Global Risk Report published by the World Economic

)RUXPHWUHPHZHDWKHUHYHQWVZLOOUDQNDVWKHPRVW

likely and impactful global risk over the next ten years.

Going forward, we will not only see system transfor-

PDWLRQVDLPLQJIRUPRUHHQYLURQPHQWDOHI¿FLHQF\EXW

also initiatives built on external hazards such as climate

change.

Our production site in Karlshamn, Sweden experienced

a really hot summer in 2018 which increased

WKHVHDZDWHUWHPSHUDWXUHDQGKDGDVLJQL¿FDQWLPSDFW

on the ability to use sea water for cooling purposes.

Instead of sea water, municipal water had to be used

JHQHUDWHPRUHHI¿FLHQF\WKURXJKWHFKQRORJ\DQG

process changes going forward.

$VPHDVXUHPHQWRIHQYLURQPHQWDOHI¿FLHQF\UHTXLUHV

integration into management and environmental plans,

it will take some time to get new sites on track with the

AAK standard. However, we can see good progress

already and with more best practice sharing, benchmarking,

scalable solutions and engagement on the

VLWHVZHDUHFRQ¿GHQWWRVHHVWURQJGHYHORSPHQWJRLQJ

forward.

in order to avoid production stop. During 2019, projects

ZHUHLQLWLDWHGWRLPSURYHRSHUDWLRQDOHI¿FLHQF\DQG

reduce sea water consumption by 50 percent. Extensive

research was completed and solutions which also aim

to reduce the overall energy consumed by the watercooling

station are planned to be implemented in 2020.

This is one example of an initiative based on external

hazards.

In order to mitigate the impact of extreme weather on

our production facilities, AAK has initiated a third-party

climate change risk assessment to be completed at all

production sites by the end of 2020. This will include a

full water-related risk assessment, which you can read

more about on page 47.

Contributes to:

41

Water consumption

Per unit processed material

-2.3%

2015 2016 2017 2018 2019

1.25

1.20

1.15

1.10

1.00

1.23

1.20

1.17

1,18

1.16

m3

:DVWHWRODQG¿OO

-48%

2015 2016 2017 2018 2019

%

5

4

3

2

1

0

1.3

1.9

2.2

4.8

2.5